Working principle of coal grinding mill feng li Medium

Oct 24, 2017· Fengli grinding mill working principle is scientific and rational, low power consumption, small footprint, to promote the realization of coal powder .

WhatsApp)

WhatsApp)

Oct 24, 2017· Fengli grinding mill working principle is scientific and rational, low power consumption, small footprint, to promote the realization of coal powder .

Under ideal working conditions, Raymond Mill consumes less energy than other ordinary grinding mills. For example, the MTM Mediumspeed Grinding Mill only consumes /h when yielding a ton of materials and /h when feeding a ton of materials. Its electricity consumption is lower than that of ball mill at the same level by over 60%.

The cement vertical mill is a grinding equipment developed on the basis of similar grinding mills, so it has many irreplaceable advantages, such as high grinding efficiency, low power consumption (2030% less power than ball mill), large drying capacity (simultaneously dry and grind materials with moisture up to 10%), large particle size of grinding materials, simple grinding process, small ...

Consumption of steel grinding media in mills – A review ... easy to generate fine particles with low hardness, ... effect of minerals in Mineral B would explain the high grinding media ...

Daswell calcium carbonate wet grinding mill is a central piece equipment to produce ground calcium carbonate powder in a wet milling way. As usual, Daswell wet grinding mill for calcium carbonate are designed to be durable and reliable machine with optimum performance. They can produce high grade calcium carbonate powder with low energy ...

High Output Low Consumption 5r Raymond Mill. raymond grinding mill is a common milling equipmentt is mainly used for the nonflammable and nonexplosive minerals, which has the mohs hardness greater than 9and the humidity below 6, like barite, calcite, glass, thermal insulation materials, etche highfine powder produced by raymond grinding mill is widely used in mining, chemical ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

One of the advantages of the SKIOLD Disc mill is that it´s possible to vary the grinding degree during operation, and thereby optimize the feed structure for different animal groups. Other advantages are its very low noise level in operation, an exceptionally long durability of wearing parts, and high capacity with low power consumption.

There are a lot of problems that most mineral processing plant meet when operating the ball mill, such as low grinding efficiency, low processing capacity, high energy consumption, unstable product fineness of the ball how to effectively improve the grinding efficiency of ball mill is an important issue for the mineral processing plants.

May 10, 2019· The liner plays the role of protecting the cylinder and end cover of the mill and lifting the grinding medium. The shape and material of liner have a great influence on the steel consumption of grinding. In addition to the traditional manganese steel liner, there are rubber liner and magnetic liner.

By increasing the level of grinding media and consequently the level of slip to above 50% of the internal volume of the mill, it is possible to rotate the grinding media with lower energy consumption than that of traditional continuous mills. Certech can guarantee savings of up to 20%.

Jan 09, 2017· The cryogenig grinder CryoMill is tailored for cryogenic grinding. The grinding jar is continually cooled with liquid nitrogen from the integrated cooling system before and during the grinding ...

A comparison of wear rates of ball mill grinding ... A comparison of wear rates of ball mill grinding ... materials consumption by wear represents a very high production cost ...

Advantages: High efficiency of powder grinding, low power consumption, big fineness of grinding materials, fineness easy to adjust, simple polytechnic procedure, less occupied area, low noise, low dust, low operation cost, low consumption of longer working life of wearing parts, and etc. Calcium Carbonate Vertical Grinding Mill Price

vertical roller mill is the compact ATOX. Offering high reliability, low installation costs and a wide range of sizes, the ATOX grinds and dries all types of coal – while providing excellent economy in terms of specific energy consumption. Versatile system The ATOX coal mill is suited for various installation types, whether inert or

Absorbing the latest grinding technology and concept at home and abroad, we have developed such a new product with international leading technology level. The device is more efficient than the ball mill, low power consumption, small installation area, and low investment for one time. Raymond Mill Grinding Process

Vertical mill is a powder mill that responds to the production requirements of energy conservation and emission reduction. It integrates crushing, drying, grinding and classifying, with more reasonable design structure, high grinding efficiency, low power consumption, large feeding particle size, and easy adjustment of product fineness.

grinding mill principle using material bed grinding material, to overcome the many shortcomings of the ball mill grinding mill mechanism, high grinding efficiency, low power consumption energysaving ball mill than 20 to 30, large drying capacity, allowing large size material into the mill, grinding process is simple, small footprint.

Highefficiency and low consumption. With the same fineness of end products and motor power, its output is two times higher than that of Jet Mill, Mix Mill, and Ball Mill. Quickwear parts with longer working life The grinding rollers and rings are made of special materials.

Mills usually operate in the range 65 82% of critical but values as high as 90% are sometimes used. A crucial parameter that defines the performance of a mill is the energy consumption. The power supplied to the mill is used primarily to lift the load (medium and charge). Additional power is required to keep the mill .

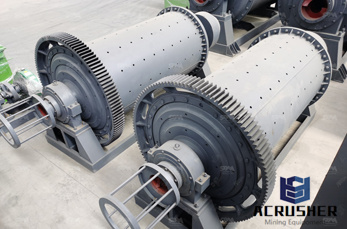

Ball mills have been the traditional method of comminution in the mineral processing industries and continue to operate with old generation classifiers, their maintenance sometimes neglected. This in combination with an inefficient operation translates into high energy consumption and low production.

The agitator cooling with the newlydeveloped Neos grinding system stands for maximum performance, product quality and efficiency. Coupled with the reliable use of extremely small grinding media, you can achieve your required product quality with high production output and low specific energy consumption.

The ball mill''s low grinding efficiency, low processing capacity, high production energy consumption, and unstable product fineness are problems that most concentrators will encounter. How to effectively improve the grinding efficiency of the ball mill is an important issue. This article summarizes 10 ways to improve grinding efficiency.

HC1700 grinding mill is a kind of large powdermaking. High fineness and low energy bentonite grinding mill. the largest ring roller mill in China, high efficiency low energy consumption, it is the first choice for ultrafine powder production, stone size range: meshes, the output is 22t/h. 1、within 200 meshes : can

WhatsApp)

WhatsApp)