(PDF) Application of air table technology for cleaning ...

The technology for beneficiation, either dry or wet methods based on the characteristics of Indian coal is highly needed at the present scenario in coal industry.

WhatsApp)

WhatsApp)

The technology for beneficiation, either dry or wet methods based on the characteristics of Indian coal is highly needed at the present scenario in coal industry.

Unrecovered and wasted coal, carbonaceous pit wastes, coal washery rejects and carbonaceous shale have energy values that in most cases can be utilised given the right technology and economic incentives. The carbonaceous material contained in overburden can have significant environmental consequences that include, the leaching of sulphuric and ...

Bharat Coking Coal Ltd., India have a large deposit of coking coal washery reject with more than 50% ash content. It is a valuable resource as there is a scarcity of coking coal in India. In the present work, the response of Indian coking coal rejects to triboelectrostatic separation at different relative humidity is studied and its potential ...

Jun 17, 2020· Topics Covered: Government policies and interventions for development in various sectors and issues arising out of their design and implementation. Supplying washed coal. Context:. The government had recently amended the Environment Protection Act to drop the mandatory washing of coal supplied to thermal power plants.. This notification undid the government''s 2016 order, which made coal ...

Dry Coal Processing A Suitable Technology for Indian Coals FGX SepTech,LLC Lexington, KY 40509 ... Dry coal processing of coal could be achieved by several techniques, utilizing various ... Washery. In all the tests, the FGX dry coal separator was able to remove the liberated rock material (about 20 ) from the ROM coal. ...

Coal Beneficiation Technology 2007 Initiatives, Policies and Practices M. Satyamurty ... – Drydeshaling: Noncoal or shalycoal is removed without using any liquid media. ... Total project cost of such plant including cost of coal washery and AFBC for using washery rejects at .

Consultancy on Coal Washery Mineral Beneficiation Plant. First time in India, Transtek has undertaken the O M of Coal Washery and Iron Ore Beneficiation with an exclusive advantage that the expertee behind are Technologist and are conversant with various Technology offered by the Plant Designers.

A graphic demonstration of the industry and environmental efficiencies gained from using Sorterra''s Dryscan dry coal processing compared with traditional coal washery. Australian company, Sorterra, have developed a patented mineral processing technology that revolutionises the way mineral resources are processed requiring no water consumption ...

Coal needs to be stored at various stages of the preparation process, and conveyed around the CPP facilities. Coal handling is part of the larger field of bulk material handling, and is a complex and vital part of the CPP.. Stockpiles provide surge capacity to various parts of the CPP. ROM coal is delivered with large variations in production rate of tonnes per hour (tph).

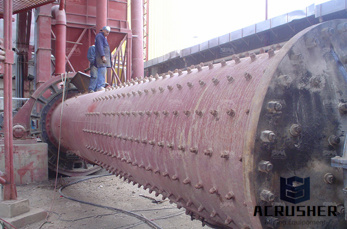

Coal Washing Plants consist of several subprocessing modules including raw coal preparation (crushing and screening station), pre discharge rejects (rom jig, dense medium vessel/bath, rotary breaker), coal feeding and washing module (jigging or dense medium cyclones) as well as a dewatering module, coal handling module (conveyors, train/truck loading station, stacker reclaimer).

May 15, 2019· Advancements in CFB Technology Provide the Best Solution for India''s Energy Future (Includes Dry FGD Seminar) » South African power producers require low cost, environmentally clean yet very reliable baseload power generation that can leverage South Africa''s vast indigenous coal resources.

the process. In addition to beneficiation of coal slurry in washery operation, the process can be utilized for recovery of the coking coal fraction from washery middlings. The tests carried out with Lodna washery middlings have similar performance parameters as with the coal slurry . The agglomerated cleans from the middlings

HOT Mining is leading in the design, construction and operation of coal washing plants (coal handling and preparation plants, hereafter "CHPP"). The Joint Venture of HOT – SCCDRI has delivered over 20 CHPPs with capacity from 90 TPH to 3125 TPH. The major engineers have delivered over 100 major coal washing projects.

Washing technology, for the proposed Hingula washery, is based on Heavy Media Separation (HM Cyclone) and the washing circuit is a closed circuit with zero water discharge. The raw coal receiving section has been designed for 2000 TPH (dry) and the washing section for 1700 TPH (dry) as required in the bid documents.

Global Coal Washery Market: Segmentation. The global market for coal washery can be classified into dry and wet processes. Before the actually washing procedure, the coal is required to be crushed and reduce into a specific size for enhanced output.

9Clean coal technology being practised in coal washeries in India, as precombustion clean coal technology, mainly focus on cleaning of coal by removing ash from coal 9Earlier only coking coal was being washed because steel making needs coking coal of ash of 17 to 18%. The raw coal ash in Indian coking coal varies from 25 to 30%. Nowadays, Min.

Coarse Coal Flotation Circuit. It is highly desirable to extend the range of coal flotation to include the coarser Sizes. Not only will this simplify general washery practice but will result in a superior product having desirable marketing characteristics for metallurgical and steam power plant uses.

Jun 17, 2020· Washing coal increases the efficiency and quality of the dry fuel. In theory, a process like coal washing was supposed to be good for everyone; thermal power plants would have fewer operational problems due to poor coal quality.

Coal washing is a process that is undertaken in a coal washery or coal preparation plant (CPP) where coal is refined or cleaned of impurities. Coal washing involves using water, mechanical techniques and relies on gravity and the difference of density between coal and it''s impurities which are usually more densely packed due to the fact that ...

Mar 20, 2020· The ash percentage in coal can be reduced by a process known as "Coal Washing" in a coal washeries which are established mostly in Jharia, Raniganj, Bokaro and Karanpura coalfields for treating prime and medium coking coals. Coal Washery by Bharat...

Coal India Limited is further looking for an established and efficient dry beneficiation technology provided there is significant potential in Indian scenario. Keywords BuildOwnOperate Washery New Business Opportunity Dry Beneficiation Winnowing Airjig XRay

At a coal washery in India, fine tailings (typically –) from the flotation circuit were thickened using a thickener and then pumped to a tailings pond. After settlement, clear water was pumped back to the washery, and solids were allowed to dry. The solids were .

The salient features of proposed expansion of coal washery are given below in the Table1. TABLE1 SALIENT FEATURES OF THE PROPOSED COAL WASHERY PLANT (4 MTPA) Sr. No Parameter Description 1 Capacity/annual through put 800 TPH 2 Washing technology Dry Process 3 Processing rate 2 X 400 TPH

January 01, 2016. An attempt has been made for exploring the possibility of dry washery in Indian context. Washing of coal by dry based technology is a holistic way of dealing with water problem of entire region. It is strongly believed that installation commissioning of washery at the pit head, dry washing of coal in particular

WhatsApp)

WhatsApp)