Cold Rolling | Steel | AMETEK Land

Temperature sensitive cold rolling operations can be accurately measured with AMETEK Land''s spot measurement thermometers.

WhatsApp)

WhatsApp)

Temperature sensitive cold rolling operations can be accurately measured with AMETEK Land''s spot measurement thermometers.

NSK Industries Cold Rolling Mill: A Manufacturer of Steel was experiencing continued failures of bearings on their Cold Rolling Mill. NSK engineers conducted an application review and found the highly contaminated operating conditions were leading to unexpected failures.

on wear is another issue. Stresses from Hertzian pressure in 4high cold mill back up rolls were measured years ago, the results were never published, but of high interest also, maybe later. K. H. Schröder July 2003 K. H. Schröder: A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL ROLLS File: SCHROEDER_ROLLS_

NDC Technologies provides the LaserSpeed Pro noncontact length speed gauge to the industry''s leading steel makers for their cold rolling mill applications. Length and speed measurements are made with better than +/% accuracy and +/% repeatability to improve product quality, increase productivity and significantly reduce manufacturing costs.

Roll stands holding pairs of rolls are grouped together into rolling mills that can quickly process metal, typically steel, into products such as structural steel (Ibeams, angle stock, channel stock), bar stock, and rails. Most steel mills have rolling mill divisions that convert the semifinished casting products into finished products.

GPT Steel Industries Ltd an ISO 9001:2008 accredited unit, was established in 2003 to manufacture Cold rolled products Tinplate products. GPT has set up complete Cold Rolling Mills (4Hi 6Hi Mill) and state of the art Electrolytic Tinplate Line (ETL) located at Gandhidham, Kutch District, Gujarat, India..

Skytech Rolling Mills Private Limited is first stainless steel cold rolling mill in india producing Stainless steel bars in custom sizes in shapes of square bar, drill rod,hollow bar,shaft,hexagon bars in steel grades,316,316L.

Achievements. A brief glance through the list of our esteemed customers is sufficient to ascertain that Nomee Industries Steel ReRolling Mills is a major supplier of steel bars of the region.

Cold rolling changes the mechanical properties of steel to better meet specifications for endless applications. COLD ROLLED STRIP Made for tight tolerances and critical surface appearance. Compared to hot rolled steel, cold rolled strip provides an improved surface and shape, and can create useful combinations of hardness, strength, stiffness ...

Kalgidhar Foundry Agro Industries (Regd.) is the oldest manufacturers Exports of Complete Steel Rolling Mills Parts Shearing Machines, 2Hi, 4Hi, Cold Hot Rolling Mill Plants for Stainless Steel, Sheet Metal Finishing Machines, Gear Boxes, Reduction Gear, Rolling Presses, Twisting Straightening Machines, Furnace Pushers High Class Casting, Sheet Shearing Machine, Rubber Mixing ...

Temper rolling is the process of lightly cold rolling sheet steel. It is typically done after the annealing process, or hot roll after pickling, to improve flatness, minimize any tendency to stretch, strain, and flute, and create a specific surface texture.

The plant includes an 86" Hot Strip Rolling mill, hot rolled strip finishing facilities (buildup, shear, and slitter lines), a 62" Continuous Pickling line, a 5Stand Cold Reduction mill, two hotdip Galvanizing lines, cold rolling equipment of Annealing and Tempering mills, and an Electric Resistance Welded Pipe mill.

NSK Industries Cold Rolling Mill: A Manufacturer of Steel was experiencing continued failures of bearings on their Cold Rolling Mill. NSK engineers conducted an application review and found the highly contaminated operating conditions were leading to unexpected failures.

The right spray technology can make all the difference in the quality and efficiency of your cold rolling process. That''s why mills depend on the experts at Spraying Systems Co. to help them select the best solution for every stage in the process — from roll cooling .

There is almost no end to the uses of highgrade steel strip in today''s world. They include everything from aircraft to beverage cans. That explains why we design our cold rolling mills to be just as versatile. What''s important to you are not only high flexibility and product quality, but also sustained, costeffective operation of your plants.

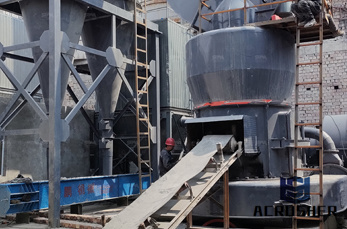

Rolling Mills Cold Rolling Mills Metal Rolling Mills Hot Rolling Mills Rolling Mill Manufacturers India Better Technologies for Brighter Tomorrows Cold Rolling is a process by which the Sheet Metal or Strip Stock is introduced between Rollers, and then compressed and squeezed.

If you need personnel, cover for staff holidays, permanent or temporary staff from bangladesh AlHaj Group of Industries. can get it done., Manpower Recruiting agent + ... One of the oldest automatic Steel ReRolling Mills from Kobe Steel, Japan. AlHaj med Ali Cold Storage. The company stores potato, foods vegetables in ...

KYCR Coil Industries Ltd. A subsidiary of KDS Group of companies has recently setup a stateofthe art Cold rolling Mill complex at Kumira 25 KM from Chittagong.

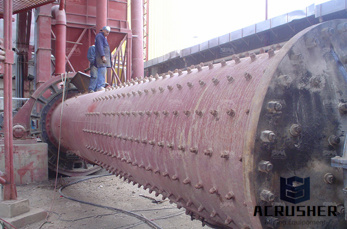

Reproducible roll barrel geometries and a faultless surface are essential for flawless products and a continuously high manufacturing quality in the cold rolling mill. The basis for high quality end products is provided by WaldrichSiegen roll grinding and electrical discharge texturing machines worldwide. First class manufacturing process

Steel: Cold Rolling, Hot Rolling Mill, Iron to steel . Steel is one of the largest industries in the world. Temperature control and detection of surface defects in key stages is essential in the steelmaking process, to guarantee product quality.

This mill is increasingly used for stainless steel strip rolling, either as inline tandem mill for cold rolling or in the entry section of hotstrip stainless steel annealing and pickling lines to roll black hot strip with highest pass reductions and simultaneous improvement of the strip shape.

Cold rolling mill complex is equipped with the most . modern stainless steel production lines, sourced from leading manufacturers of the world. Coil build up line, bell anneal furnaces continuous annealing and pickling lines, sendzimer mills, skin pass mill, strip grinding line, slitting and .

Steel. Cold Rolling. Cold rolling occurs when the temperature of the material is below the recrystallization temperature. During this stage it is important to detect surface defects for saving valuable time, increase production efficiency and gain faster line speed through automated surface inspection. Hot Rolling Mill

Cold rolling mills are under pressure to produce more, higherquality steel. Equipment needs to cope with demands of greater dimensional accuracy, improved surface quality, higher steel grades and output speed. All this while overcoming the daily challenges of high precision, high loads, high speeds and aggressive coolants.

WhatsApp)

WhatsApp)