Start Up Sequence of a Loesche Coal Mill YouTube

Jun 18, 2013· How Vertical Grinding Mills Work (Coal Pulverizer Example) Duration: 14:39. saVRee 3D 14,320 views. 14:39. JK Lakshmi Cement Manufacturing Process Duration: 4:12.

WhatsApp)

WhatsApp)

Jun 18, 2013· How Vertical Grinding Mills Work (Coal Pulverizer Example) Duration: 14:39. saVRee 3D 14,320 views. 14:39. JK Lakshmi Cement Manufacturing Process Duration: 4:12.

coal milling, coal milling Suppliers and Manufacturers at ... There are 438 suppliers who sells coal milling on Alibaba, mainly located in Asia. The top countries of suppliers are China, Taiwan, China, and India, from which the percentage of coal milling .

Jun 14, 2019· Learn about vertical grinding mills and coal pulverizers! We look at all of the vertical grinding mill''s main components, how it works and some .

Vertical coal grinding mill integrates crushing, drying, grinding, powder selection and conveying.; It has simple system and compact structure. Vertical coal mill covers an floor area about 50% of the coal ball mill with the same specification.; Coal vertical mills can work in openair environments, greatly reducing the cost of investment. The design of the vertical coal mill system is simple ...

Vertical roller mill can replace ball mills or tube mills used for preparing coal. Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding. Grinding media wear in a VRM will only be 5 to 10 g/ton of coal powder, as compared to 100 g/ton of coal powder in a ball mill.

We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades. The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials. It is increasingly used as a solution for efficient grinding.

To summarize the coal mill controls, they may be divided basically into two major categories:. 1. To control the quality of coal being sent to the burners located on the furnace walls. The word quality here means the temperature and fineness of the PF. The set temperature values are dependent on the percentage of volatile matter that exists in the main fuel.

Sep 24, 2012· [Vertical Mill] and [vertical coal mill] is easy installed and easy for maintainence. ... Identification and Selection of Plant and Machinery, Manufacturing Process and or Equipment required, General Guidance, Technical and Commercial Counseling for setting up new industrial projects on the following topics. ...

Vertical roller mill equipment is the special powder grinding mill equipment to meet the coal milling market. We provides perfect presales, midsales and aftersales services. We have a wealth of experience in EPC general contracting services and are able to customize special selection and configuration plans according to the production needs ...

Vertical roller mill can replace ball mills or tube mills used for preparing coal. Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding. Grinding media wear in a VRM will only be 5 to 10 g/ton of coal powder, as compared to 100 g/ton of coal powder in a ball mill.

Slag Powder Making Model Selection Program. Hlm vertical grinding mill can be widely used in electricity metallurgy cement chemicals nonmetallic mineral industries mainly used for grinding and processing of cement raw material clinker power plant desulfurization limestone powder slag powder manganese ore gypsum coal .

Vertical roller mill equipment is a special production equipment of HCM, which is also a largescale coal mill equipment favored by customers and market. The grinding mill used in the field of coal mine is more professional, because the coal powder is inflammable and explosive, only the special grinding mill can realize the safe and efficient ...

Vertical Mill CITIC Heavy Industries Company Ltd. If you need vertical slag mill, please don''t hesitate to contact us. CITICIC began in 1956 The largest mining machinery manufacturer and one of the .

Today the airswept vertical roller mill is the standard solution for coal grinding installations. And thanks to our continuous refinement of the ATOX coal mill over the years, today''s leading airswept vertical roller mill .

Pulverized coal mills with throats that are too wide will have corresponding low throat velocity in the mill grinding zone that contributes to excessive coal rejects and fires. This is an example ...

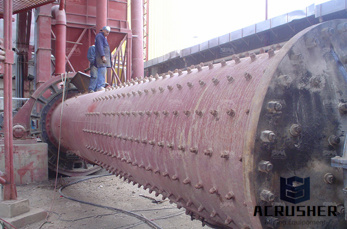

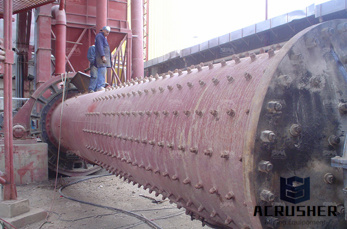

Pulverized Coal Injection Project, coal mill. Blast furnace PCI /rotary kiln PCI/vertical kiln PCI have been the main method for lime stone roasting, pellet roasting, coking, iron increasing, reduced cost, improve high efficiency smelting,and promote blast furnace running smoothly, also is the main method for technical progress of blast furnace iron making.

According to the production needs of coal gangue powder, we scientifically customize the selection and configuration of vertical mills to help the project create value. 1. What is coal gangue? Coal gangue is a solid waste generated during the production and processing of coal, and its annual emissions are equivalent to about 10% of coal production.

As a vertical mill manufacturer, Guilin Hongcheng supplies petroleum coke ultrafine vertical grinding equipment with high grinding efficiency and low energy consumption, and provides tailormade services according to the needs of each customer''s milling, equipped with scientific and rational configuration. The complete setting configuration of petroleum coke ultrafine vertical grinding mill ...

Pulverized Coal Vertical Mill, also known as Coal Pulverizer, is widely used in coal industry, cement industry, chemical industry, electric power industry, and other industry which is the largescale material grinding and superfine grinding processing. It is the ideal milling industry assembly equipment of crushing, grinding, drying, classification and conveying, being used for pulverized coal ...

The Raymond® Bowl Mill is considered the finest vertical roller mill available for pulverizing coal. The typical Raymond bowl mill system is designed to simultaneously dry, pulverize, and classify solid .

Chaeng coal grinding system specifications are divided into: coal vertical mill, coal mill, coal mill, its capacity design is divided into: 20t / h, 25t / h, 40t / h, in order to meet the market demand for a variety of coalfired boiler applications, and the pulverized coal mill .

In the field of coal gangue grinding, vertical roller mill equipment is highoutput, efficient, environmentally friendly and energysaving. And the whole production line process is scientific, you are welcome to come to the factory to know the details of coal gangue vertical roller mill equipment. Tel:+ Email: hcm

With adequate mill grinding capacity, a vertical mill equipped with a static classifier is capable of producing a coal fineness up to % or higher <50 mesh and 80% or higher <200 mesh, while one equipped with a dynamic classifier produces coal fineness levels of .

Application of Vertical Mill In Pulverized Coal. In order to meet the needs of energy saving and environmental protection, many power plants choose or switch to a more advanced vertical roller mill (also called vertical roller mill) system for coal .

WhatsApp)

WhatsApp)