110V Soybean Grinding Machine Tofu Soymilk Beater Pulping ...

70KG/H Soybean Grinding Machine Soymilk Machine Pulping Milk Machine 1100W1800W. 1 X Soymilk. ★ This product is a high quality beater, its separator is the ideal food machine to process .

WhatsApp)

WhatsApp)

70KG/H Soybean Grinding Machine Soymilk Machine Pulping Milk Machine 1100W1800W. 1 X Soymilk. ★ This product is a high quality beater, its separator is the ideal food machine to process .

grinding machines perform the dressing task automatically. The application of coolants to the grinding process is important. Coolants reduce grinding machine power requirements, maintain work quality, stabilize part dimensions, and insure longer wheel life. Coolants are either emulsions, synthetic lubricants or special grinding oils.

Grinding Process. The grinding wheel consists of several abrasive particles which act as minute cutting edges, and these particles are bonded with the help of bonding material. The advantage of using such a process over conventional metal removal processes are as follows. The rate of removal of material .

Plastic Grinding. Demand is growing for recycled plastics, 1 and plastic grinding is the fastest, easiest way to process your plastics from PVC to PET back into reusable material.

Sheet Metal Materials; Vices; Hand Tools. File Tool. Parts of File Tool; Types of File Tool; Hacksaw; Hammer; Try Square; Chisel; Conventional Machining Process. Lathe. Lathe Accessories. Lathe .

Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or grinding wheel against it along a controlled path. Honing is .

Normally it is considered that material removal rate in grinding process is lower while better surface finish and precision will be secured in grinding process, but these days with advancement in technology for development in grinding wheel and grinding machine, we are introduced with abrasive machining where better precision and surface finish with high material .

Dec 23, 2018· The grinding process has the least material removal rate among other machining processes because of the following reasons Size effect: As above discussed the machining is done by the abrasive action of grinding wheel that''s why a large portion of the abrasive will be embedded inside the wheel and a small portion of abrasive will be allowed ...

Jul 14, 2020· Grinding machine grinding machine food processor grain dry crushing medicinal materials.

materials, such as single crystal sapphire can not be finished via form grinding due to processinduced cracks • Diamond turning center can be used for non ferrous materials but it is a superprecision machine .

Machine Tool Definition: A machine tool is a powerdriven device used for sizing, shaping, and processing of a product to the desired accuracy by removing the excess material in the form of chips. ... Grinding wheel, Drill bit etc. ... It is a process in which a piece of raw material is cut into a desired shape and size using sharp cutting ...

These machines include the: Belt grinder, which is usually used as a machining method to process metals and other materials, with the aid of coated to a belt sander (which itself is often used for wood but sometimes metal). Belt grinding is a versatile process .

A Machine That Processes Materials By Grinding Or . Processes Of Grinding Machine Thirstycrow It well fits for crushing numerous medium and soft materials, such as limestone, feldspar, calcite, talc, barite, clay,.Processes of grinding machine.

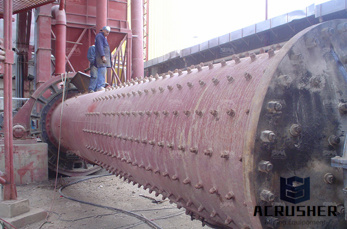

A Machine That Processes Materials By Ball Mill Or Crushing. A Machine That Processes Materials By Ball Mill Or Crushing Ball mills introduction ball mills are the key equipment for grinding after materials are crushed at crushing plant ball mill is an efficient machine for fine powder grinding which employ high carbon steel or ...

Jun 13, 2018· Grinding can be done wet or dry, depending on the process in use, but for dry grinding the materials first may need to be dried in cylindrical, rotary dryers. Many machines are used for grinding.

By carefully selecting the grinding parameters and controlling the process, ceramic materials can be ground predominantly in a ductile mode resulting in relatively smooth grooves on the surface. Ductilemode grinding can be implemented on a conventional grinder .

Cruching And Grinding Processes. Grinding machinegrinding machine for grinding machine description of grinding machine this grinding machine often shortened to grinder is mainly used for grinding surfaces of work pieces to become exact dimensions and it can process many kinds of materials .

Grinding Material removal process in which abrasive particles are contained in a bonded grinding wheel that operates at very high surface speeds •Grinding wheel usually diskshaped and precisely .

Processes include turning, milling,.Electronics and new "powder" metallurgy machine is used the grinding stone of which is a conductor material. Read More Cnc Machining Services Machine .

Currently electrochemical grinding (ECG) machines, developed by Everite Ltd are the only commercial combined hybrid machine tools that combine both grinding and ECM processes. UG 824 [11] is an ECG surface grinder machine tool. It is able to process any conductive material .

A belt grinder includes a machining process to grind metals and other materials, with the help of coated abrasives. Belt grinding is a versatile process that involves several kinds of applications such as stock removal and finishing. A jig grinder .

Surface Grinding Machines and Process. Surface Grinding is a manufacturing process which moves or grinding wheel relative a surface in a plane while a grinding wheel contacts the surface and removes a minute amount of material, such that a flat surface is created. The term surface grinding designates any process which accurately processes .

Abrasive machining involves material removal by the action of hard, abrasive particles. The use of abrasives to shape parts is probably the oldest material removal process. They are important because Introduction They can be used on all types of materials ranging from soft metals to hardened steels and hard nonmetallic materials .

New grinding process developments by Tyrolit, and machine tool developments by Makino, are changing that thought process. Utilizing new grinding techniques, incredible material removal rates .

WhatsApp)

WhatsApp)