Cement Manufacturing YouTube

Jul 31, 2013· For more information: info info ...

WhatsApp)

WhatsApp)

Jul 31, 2013· For more information: info info ...

Stainless Steel Tube Products Available. PJ Tube''s partnership with Webco Industries provides customers with a vertically integrated supplier, with tube mills and valueadd finishing facilities all under one umbrella. We offer wide range of welded, weldedanddrawn, and seamless stainless steel tube and pipe to meet your unique needs.

a global specialty manufacturer Since 1924, Plymouth Tube has been a global specialty manufacturer of carbon alloy, nickel alloy, and stainless precision steel tubing. Plymouth Engineered Shapes manufactures titanium, stainless, nickel alloy, carbon alloy semifinished extrusions and semifinished shaped bar.

CEMENT MANUFACTURING – A WET PROCESS WITH THE FLOW DIAGRAM. In the wet process, 1) The raw limestone from quarries is first crushed to small size fragments. Then it is mixed with clay or shale in ball or tube mill and ground to form a slurry of a fine consistency with the addition of water.

China Cement Mill manufacturers Select 2020 high quality Cement Mill products in best price from certified Chinese Mill manufacturers, Grinding Equipment suppliers, wholesalers and factory on

China shenghui machinery (CSM) is a professional cement equipment manufacturing enterprise,the main products are cement production line including:tube mill,rotary kiln,roller press,vertical mill, rotary dryer,suspension preheater.

China Sunrise Machinery (CSMcement production line) is a professional cement equipment manufacturing enterprise,Five types of the products have get European CE certification, meanwhile it owns about 30 patented products hightech products. The main products are cement production line including:tube mill,rotary kiln,roller press,vertical mill, rotary dryer,suspension preheater.

Course Program. Module 1: An introduction to the Cement Manufacturing. This module addresses the fundamental principles of cement production. Module 2: Raw materials for cement manufacture. In the cement industry, the quarry is the extraction method for the production of raw materials in the cement manufacturing process.

The company specializes in manufacturing tube mills, rotary kilns, vertical roller mills and large steel casting and can undertake the EPC projects of cement production lines, active lime production lines, blast furnace slag/ steel slag/ nickel slag grinding plants, and its products are sold to more than 50 countries and regions in Southeast ...

The preliminary grinding is achieved by using a gyratory type of crushers whereas for fine grinding use is made of tube mills. The tubemill crushers are generally provided with air separators through which material of desired fineness can only pass. The coarser, portion of the cement is fed back into the mill .

Aug 30, 2012· This saves the extra fuel cost and makes cement somehow economical. Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant. There are also various other raw materials used for cement manufacturing. For example shale, fly ash, mill scale and bauxite.

The preliminary grinding is achieved by using a gyratory type of crushers whereas for fine grinding use is made of tube mills. The tubemill crushers are generally provided with air separators through which material of desired fineness can only pass. The coarser, portion of the cement is fed back into the mill for further grinding.

Cement Tube Mill, Wholesale Various High Quality Cement Tube Mill Products from Global Cement Tube Mill Suppliers and Cement Tube Mill Factory,Importer,Exporter at learn more "art" than engineering and the equipment manufacturers be applied in cement grinding optimisation.

Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement ki...

As a professional manufacturer of tube mills in China, we have the largest production and export base of concrete equipment in the coastal areas. Our products mainly consist of cement production line, rotary kiln, cement mill, slag mill, cement grinding equipment, preheating equipment, conditioning tower, electrical control equipment, etc.

Cement Manufacturing Process Flow Chart Crusher. In the cement manufacturing process, each producing 1 tons of cement grinding material at least 3 tons (including fuel, clinker, gypsum, mixture and all kinds of raw materials), according to statistics, dry process cement production line grinding operation requires more than the consumption of power plant power accounts for .

Oct 23, 2015· Cement is an energyintensive industry in which the grinding circuits use more than 60 % of the total electrical energy consumed and account for most of the manufacturing cost [].The requirements for the cement industry in the future are to reduce the use of energy in grinding and the emission of CO 2 from the kilns. In recent years, the production of composite cements has been .

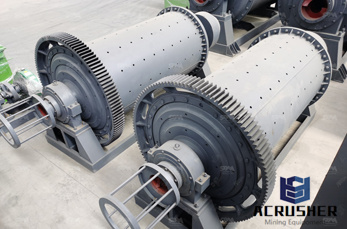

They crush minerals, ores, coal, or cement clinker by impact and friction until the material is pulverized. The tube mills, which can have a diameter of up to 15 m and a length of up to 20 m, are installed horizontally. With tube mills, a distinction is made between different drive variants. FLENDER particularly specializes in: Single pinion drives

Cement Manufacturing Process Flow Chart Crusher. In the cement manufacturing process, each producing 1 tons of cement grinding material at least 3 tons (including fuel, clinker, gypsum, mixture and all kinds of raw materials), according to statistics, dry process cement production line grinding operation requires more than the consumption of power plant power accounts for about 60%, the rawget ...

China Sunrise Machinery (CSMcement production line) is a professional cement equipment manufacturing enterprise,Five types of the products have get European CE certification, meanwhile it owns about 30 patented products hightech products. The main products are cement production line including:tube mill,rotary kiln,roller press,vertical mill, rotary .

Manufacturing the cement kiln most portland cement is made in a rotary kiln basically this is a long cylinder rotating about its axis once every minute or two the axis is inclined at a slight angle the end with the burner being lower,Tube Mill In Cement Manufacture.

The clinkers as obtained from the rotary kiln are finely ground in ball mills and tube mills. During grinding, a small quantity, about 3 to 4 per cent, of gypsum is added. The gypsum controls the initial setting time of cement.

China Tube Mill manufacturers Select 2020 high quality Tube Mill products in best price from certified Chinese Mill manufacturers, Tube Machine suppliers, wholesalers and factory on

SMS group has more than 130 years of experience in the production of tubes and pipes and is the only provider able to offer the full line of products and services for steel tube production. Its roots go back as far as 1885, when brothers Reinhard and Max Mannesmann obtained the first patent for the manufacture of seamless tubes – a pioneering ...

WhatsApp)

WhatsApp)