Threestage gear unit for vertical mills YouTube

Feb 26, 2013· The WPV threestage bevel and planetary gear units, all of which are equipped with slide bearings, have reached an impressively compact design. This is made ...

WhatsApp)

WhatsApp)

Feb 26, 2013· The WPV threestage bevel and planetary gear units, all of which are equipped with slide bearings, have reached an impressively compact design. This is made ...

Dec 04, 2017· root cause analysis of failure and repairing and bearing replacement of vertical roller mill gear box of cement factory.

Our gear units work efficiently and reliably with the various types of horizontal mills in the cement and mining industries. We provide both central and lateral drive systems that use multistage spur gears, planetary arrangement or simple girth gear pinion drives – whatever best suits your requirements.

The COPE gearbox is primarily available for mill outputs between 4000 and 12 000 kW and represents a highly redundant innovative drive system for large and very large vertical mills, offering up to 8 motors at the motor end. As this power train retains the normal dimensions, the system is also suitable for retrofit gearboxes in existing mills.

The gear unit represents an almost integral component of the mill. The output flange of the gear unit is rigidly connected with the grinding table. In addition to transmitting the torque,the gear unit also has capability to take up the reaction forces from the the griding force of the mil''s rollers.

Jun 24, 2015· The mill will produce 205t/hr CPC 30 cement at 4000 Blaine or 195t/hr CPC 40 cement at 3700 Blaine. The order also includes a LDC classifier (Loesche Dynamic Classifier), as well as the COPE gearbox, including gearbox drive motors, developed in cooperation with RENK AG.

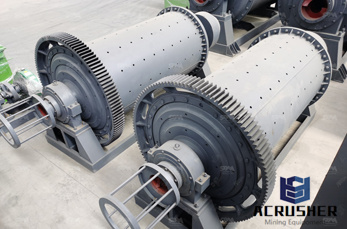

We are engaged in manufacturing and supplying Girth Gear, Industrial Girth Gear, Kiln Girth Gears. This girth gear is widely demanded in different industries to be installed in different machines such as Rotary Kilns, Rotary Dryers and Ball Mills, girth gear for ball mill, girth gear for cement mill, girth gear for raw mill, girth gear for rod mill, gear for ball mill, gear for rod mill, gear ...

Extensively field tested and proven in harsh cement applications, our mill drive gearboxes cover all grinding applications up to 10 MW per drive and we have single, double and triple reduction gearing available depending on the required ratio and motor speed. Ball Mill Gearbox Features

Stotz Gears Pvt. Ltd. Offering Cement Mill Girth Gear, गर्थ गियर at Rs /piece in Ghaziabad, Uttar Pradesh. Read about company. Get contact details and address| ID:

Cement; Crushing Grinding; Ball Mill Drives. We can provide all elements of a mill drive system as a fully optimised solution to suit your process exactly, or individual mill drive gearboxes, girth gears, pinions and couplings as required.

Roller Mils are directly driven bevelwheel planetary gears or bevel cylindrical gear units. The gear unit represents an almost integral component of the mill. The output flange of the gear unit is rigidly connected with the grinding table. In addition to transmitting the torque,the gear unit also has capability to take up the reaction forces from the the griding force of the mils rollers.

Cement mill gearbox gearbox for cement industry is the core of transmission equipment in cement production system,including reducer for vertical roller mill,reducer for central drive tube mill,reducer for side drive tube mill,gearbox for unilateral double tube mill,planetary gearbox for rolling press and planetary gearbox for central drive.

Meet ELECON, who Epitomizes cutting edges technology and path breaking innovation that have made us supplier of choice for cement companies. Backed by a proven track record, spanning well over six decades and driven by unwavering excellence, Elecon is all set to meet the changing requirements of the cement industry and churn out technologically superior product from time to time.

One of Biberci Insaat''s first investments for the new greenfield cement plant is the order of Loesche''s LM +3 cement mill for clinker grinding. The mill will produce 200t/hr of Ordinary Portland Cement at 3,800 Blaine. The gearbox is planned with a capacity of .

To cater to the increasing demands of the cement industry, we offer a wide range of products for various applications. We provide a variety of industrial gearboxes like helical models, as well as spur and bevel gearboxes to this industry. Essentially, the cement industry uses industrial gearboxes to alter torque to the maximum possible extent.

Overview. Top Gear have created global foot prints in this segment all over the world by supplying cost effective, reliable and high performance products in this field with our expertise and command on various sugar processes and applications.

Kabir. A Enterprises Offering Cement Mill Gear, मिल गियर, Cement Mill Gear in Chakan, Pune, Marashtra. Read about company. Get contact details and address| ID:

In the Cement industry gearboxes are supplied for kiln roller drives, crusher gearboxes and conveyor drives. The gearboxes are designed to operate in harsh conditions with minimum maintenance and long life. Conveyor gearboxes are supplied as motor gearbox combinations with backstops, brakes, complete with bedplates and antirotation arms.

Wholesale Trader of Cement VRM Gearbox Seisa Gearbox For Vertical Rolling Mill VRM AIR PREHEATER offered by Adroit Gear Transmission, Wadhwan, Gujarat.

large cement mill in Donetskaya Ukraine Europe,Lafarlcim is the global leader in building materials and solutions and active in four business segments Cement Aggregates ReadyMix Concrete and Solutions Products It is our ambition to lead the industry in .

Roller Press Gearbox. As the roller press gearboxes rotate in two opposite directions, small, dry particles are crushed into powder or uniform shapes. These particles also experience extremely high pressure. In the cement industry, the roller press can be applied to raw material, pregrinding, and cement .

For the preparation of cement raw material, cement, and granulated blastfurnace slag with small to medium output rates, the MVR mill with conventional drive is the right choice. This mill type is by the way the core piece of our modular ready2grind system.

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications. It is designed along sound engineering principles ...

Cement MAAG® GEAR MAX Drive for vertical roller mills. December 12, 2019. Our MAAG® GEAR MAX Drive is a modular drive system delivering highest power for your vertical... 00:26. Cement Hope Cement project. March 05, 2020. Customer story about a kiln project at Hope Cement.

WhatsApp)

WhatsApp)