Milling Formulas and Worksheet YouTube

Dec 17, 2015· Calculating Cutter RPM, Table Feed, Cuting Time, and Metal Removal Rate.

WhatsApp)

WhatsApp)

Dec 17, 2015· Calculating Cutter RPM, Table Feed, Cuting Time, and Metal Removal Rate.

Apr 14, 2016· Our selection of Hardinge manuals have grown over the years, and we''ve always tried to provide the best quality Hardinge Lathe and Mill manuals possible. We were recently contacted by one of our customers Lee Backulich. He has collected Hardinge equipment for years, and has a lot of documentation on them. He was quite [.]

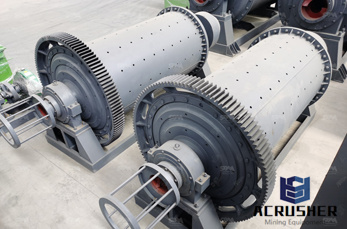

Keywords: Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc.

PQN04 series planetary ball mills may be used for mixing, homogenizing, fine grinding, mechanical alloying, cell disruption, small volume hightech material production and even colloidal grinding. They are the ideal wet/dry milling tools for acquiring research samples with high efficiency and low noise. Vacuum jars may be used to process sample within a vacuum environment.

Grizzly Industrial®, Inc. is a national retail and internet company providing a wide variety of highquality woodworking and metalworking machinery, power tools, hand tools and accessories. By selling directly to end users we provide the best quality products at the best price to professionals and hobbyists.

Milling Speeds and Feeds Charts. The most important aspect of milling with carbide end mills is to run the tool at the proper rpm and feed rate. We have broken these recommendations down into material categories so you can make better decisions with how to productively run your end mills.

Ball mills can be used to further break down or refine a single material, or you can place multiple materials into a ball mill jar to mix as you pulverize this is a very common industrial solution for mixing glazes that require the smallest of mesh sizes. Ball mills basically function like a mortar and pestle, but on a much larger scale.

proposed flowsheet consists of existing SAG mill circuit followed by a new proposed ball mill in closed circuit with the existing hydrocyclone package. In all simulations, SAGT, CYCL and MILL models were selected to simulate SAG mill, Hydrocyclone packages and ball mill units.

Apr 03, 2014· • It includes models for crushers, autogenous mills, ball mills, rod mills, screens, and hydrocyclones. • It is a closed package: you can not add your own process models. • There is detailed information on the models included with JKSimMet in the user manual. 3.

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

excel c12 ball mill manual. FLzenith ball mill for cement grinding. on standard modules. 2. The FLzenith ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement. The mill may operate... Read More. Dhaka at a glance Table C12 : .... A verbatim training manual was prepared and used for ...

EX270SF with Select Fire A high capacity studio model. NOTE: Width dimension includes control box and height includes the stand (8") on all EXCEL® kilns. Fires to Cone 10 (240V single or three phase, 208V three phase); Cone 6 (208V single phase) Select Fire™ Standard Computer controlled firings are more convenient and accurate. Now includes EZLIFT Heavyduty, springloaded hinge means ...

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications.

4 Flute Carbide Ball End mills excel in peripheral milling and finishing. 4 Flute end mills provide a much finer finish and can be ran at faster rates. The hemispherical tip produces rounded details, where sharp corners must be av...

MATERIAL BALANCE IN FROTH FLOTATION USING MICROSOFT EXCEL SOLVER. ... Material balance in froth flotation using Microsoft Excel Solver ... Ball mill flow diagram (ball mill inlet pulp ...

Overview of all Retsch videos: product explanations, function principle animation as well as handling videos with operating instructions. View now!

Home > Products > Equipment for Battery > Coin Cell Manual Coin Cell Crimper The world standard manual coin cell crimper for 2016 and 2032 in Lithium ion battery RD. Very ...

If P is less than 80% passing 70 microns, power consumption will be. Ball Mill Power Calculation Example. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work ...

OPTIMIZATION OF THE SAG MILL CIRCUIT AT KINROSS PARACATU BRAZIL. ... Further simulations were performed to evaluate a circuit expansion, with the inclusion of a third ball mill.

Manual Instruction Ok Cement Grinding Mill Fluser manual of grinding mill for cement . ball mill maintenance,ball mill operation,ball grinding mill,FL . ba. Largescale crushing screening milling plants. Offer efficient, costeffective services for you. +7(927)687 07 58 .

Planetary Mills are ideally suited for fine grinding of hard, mediumhard, soft, brittle, tough and moist materials. The comminution of the material to be ground takes place primarily through the highenergy impact of grinding balls in rotating grinding bowls.

100°C, depending on the milling cup size, ball filling, speed and milling time. The PM400 is fitted with a ventilator which sucks the waste heat produced during milling directly out of the milling suction volume per hour is greater than 20 times the milling chamber volume.

Today, Excel is renowned as a fullline provider of high performance crusher replacement parts, mill lift inserts, undercarriage components for many models of shovels and a growing line of replacement parts for largescale openpit mining equipment.

Aug 19, 2018· Ball Mill Cutter. Ball cutters are also famous as ball nosed cutters. You can be easily identified as ball cutters as their end is hemispherical in shape. Ball cutters are used to decrease the stress concentration and are also known as ball end mills. Whenever there is a need of cutting threedimensional shapes then, there is a use of ball ...

WhatsApp)

WhatsApp)