Used Milling Machines for Sale | Bid on Equipment

A devise that breaks solid materials into smaller pieces by grinding, crushing or cutting. Milling covers a wide variety of difference operations and machines.

WhatsApp)

WhatsApp)

A devise that breaks solid materials into smaller pieces by grinding, crushing or cutting. Milling covers a wide variety of difference operations and machines.

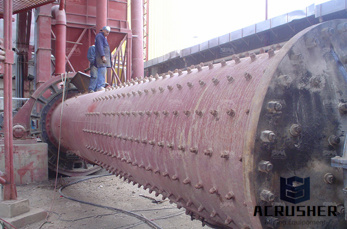

The ball mill machines mainly include: raw mill, coal ball mill, ore ball mill, small ball mill, wet ball mill, ceramic ball mill, overflow ball mill, as well as vertical ball mill, rod mill and automatic/semiautomatic mill and other industrial milling equipment. These industrial ball mills are widely used in cement manufacturing, mining ...

Fits for most milling machines, include Bridgeport and Bridgeportstyle. 1 x Ball Crank Handle. Inside bore: approx. 1X F ootball handle. Model: D26.

Inventory ID: 6CCM02. UNUSED 22'' x 38'' (6706mm x 11582mm) Ball Mill, 10,000 kW (13405 HP) Twin Pinion 50 Hz Motors and Gear Reducers

Aug 06, 2020· Orbis Machinery, LLC is an independent, ownermanaged design, engineering and manufacturing company of process equipment. With nearly 60 years of combined process and engineering knowledge, Orbis Machinery specializes in double arm mixers, tumble and ribbon blenders, ball mills and rolling mill solutions for the process industry.

Making a ball mill 4 steps nov 24, 2012 making a ball mill from a sewing machine motor, a broom stick and some scrap woodhere doesnt seem to be any proper ball. Ball Milling Method Ball mill grinds monomers into polymer chemical chemists commonly use ball .

Aug 10, 2020· The leading business directory of used metalworking machinery, used machine tools, industrial fabrication equipment, chemical processing equipment, presses, pumps, furnaces .

UsedMPT Ball Mill, Type MPT 300. UsedMPT Ball Mill, Type MPT 300. 117" (3000 mm) diameter x 39" (1000 mm) deep milling chamber. Max milling capacity 10 tonnes (10000 kgs) per hr. Corn size 103000 um. Max milling chamber capacity cubic feet ( m3). Max milling speed 24 RPM by a HP/75 Kw, 3Ph/50cycle/380volt motor.

Powerful impact ball milling results in a perfect grinding efficiency. The Autofill system avoids direct contact with LN 2 and makes cryogenic grinding very safe . Its versatility (cryogenic, wet and dry grinding at room temperature) makes the CryoMill the ideal grinder for quantities up to 20 ml.

A wide variety of ball mill machine price options are available to you, such as ball mill, raymond mill. There are 1,725 suppliers who sells ball mill machine price on, mainly located in Asia. The top countries of supplier is China, from which the percentage of ball mill machine .

Ball mill equipment primary machine in belize offers 7,507 ball milling equipment products. about 12 of these are mine mill, 11 are grinding equipment, and 1 are ceramics. a wide variety of ball milling equipment options are available to you, there are 7,518 ball milling equipment .

UsedMPT Ball Mill, Type MPT 300. UsedMPT Ball Mill, Type MPT 300. 117" (3000 mm) diameter x 39" (1000 mm) deep milling chamber. Max milling capacity 10 tonnes (10000 kgs) per hr. Corn size 103000 um. Max milling chamber capacity cubic feet ( m3). Max milling .

The ball mill equipment developed by FTM Machinery is a grinding machine, which uses steel balls as the grinding medium. And the ball mill grinder is mainly used for grinding cement, silicate products, new building materials, refractory materials, fertilizers, various ores and glass ceramics, etc.

Milling is a machining process in which a rotating milling tool removes material from the surface of a piece of stock. It is used to create parts with a wide range of shapes and features, such as pockets and slots. Milling tools are installed on a CNC (computer numerical control) or manually controlled milling machine to perform milling tasks.

Making a ball mill 4 steps nov 24, 2012 making a ball mill from a sewing machine motor, a broom stick and some scrap woodhere doesnt seem to be any proper ball. Ball Milling Method Ball mill grinds monomers into polymer chemical chemists commonly use ball mills to grind materials into powders and mix them together, yet few groups use the.

High Efficiency and Fine Granularity Stirred Ball Mill Machine Of Production Type Less Vibration Mini Stirred Ball Mill Equipment 1600Liter Laboratory Compact Stirred Ball Mill Machine

Find details of companies offering ball milling machine at best price. Listed manufacturers, suppliers, dealers exporters are offering best deals for ball milling machine.

End milling An end mill makes either peripheral or slot cuts, determined by the stepover distance, across the workpiece in order to machine a specified feature, such as a profile, slot, pocket, or even a complex surface depth of the feature may be machined in a single pass or may be reached by machining at a smaller axial depth of cut and making multiple passes.

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill .

Milling Equipment. Milling Equipment Ball grinder machine A class of machinery and equipment that can be used to meet the production requirements of coarse grinding, fine grinding and super fine .

abeokuta ball pressing machine price. Milling Equipment abeokuta ball pressing machine price A class of machinery and equipment that can be used to meet the production requirements of coarse .

The Litchco Jig is taller than other ball jigs which reduces the clearance, so the length of nonPBA cut bits are more difficult and slower when changing bits. Standard drill bits without the PBA cut have a 13/4" tail but for PBA Cut Bits, we remove 3/4" of the tail, leaving the chuckable portion of the bit at 1".

Roller Mill Jars and Planetary Mill Machinery and Equipment. In addition to our milling media, we offer for sale milling and roller jars made specifically for use in planetary mills and roller mill machines. Roller milling is considered the most economical and common method of powder processing. Our jars are complete with gasket, lid and clamps.

Ball mill grinding machine is a kind of horizontal drumtype grinding mill with external gear and double bins. Materials goes evenly through quill shaft in feeding device into the first bin, which has ladder .

WhatsApp)

WhatsApp)