Chapter 4 Introduction to Process Technology Flashcards ...

Start studying Chapter 4 Introduction to Process Technology. Learn vocabulary, terms, and more with flashcards, games, and other study tools.

WhatsApp)

WhatsApp)

Start studying Chapter 4 Introduction to Process Technology. Learn vocabulary, terms, and more with flashcards, games, and other study tools.

"Strip mining" is the practice of mining a seam of mineral, by first removing a long strip of overlying soil and rock (the overburden).It is most commonly used to mine coal and lignite (brown coal).Strip mining is only practical when the ore body to be excavated is relatively near the surface.

Coal needs to be stored at various stages of the preparation process, and conveyed around the CPP facilities. Coal handling is part of the larger field of bulk material handling, and is a complex and vital part of the CPP.. Stockpiles provide surge capacity to various parts of the CPP. ROM coal is delivered with large variations in production rate of tonnes per hour (tph).

Industrially, the most common dense media is a suspension of fine magnetite and/or ferrosilicon particles. An aqueous solution as a dense medium is used in coal processing in the form of a belknap wash and suspensions in air are used in waterdeficient areas, like areas of China, where sand is used to separate coal from the gangue minerals.

Screen Panels. With a complete range of modular screen panels for mineral processing, Multotec ensures your screen deck is optimised to achieve your required cut size efficiently, reliably and over an extended service life.. Our compression and injectionmoulded rubber, polyurethane, wedge wire, ceramic, steel and trommel screens are used in plants across the world processing a range of ...

Coal gasification is the process of producing syngas–a mixture consisting primarily of carbon monoxide (CO), hydrogen (H 2), carbon dioxide (CO 2), natural gas (CH 4), and water vapour (H 2 O)–from coal and water, air and/or oxygen. Historically, coal was gasified to produce coal gas, also known as "town gas". Coal gas is combustible and ...

Coal is a combustible black or brownishblack sedimentary rock composed mostly of carbon and hydrocarbons. It is the most abundant fossil fuel produced in the United States. Coal is a nonrenewable energy source because it takes millions of years to create. The energy in coal comes from the energy stored by plants that lived hundreds of millions of

Dec 27, 2018· According to Kentucky Coal Education, continuous miners consist of a series of large cutting shearers and a selfraising hydraulic system that supports the mineshaft ceiling as sections of coal are removed. Rock Duster. Rock dusters are pressurized pieces of equipment that coal miners use to spray inert mineral dust over highly flammable coal dust.

1 Froth Flotation – Fundamental Principles Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces in a mineral/water slurry. The particles with attached air .

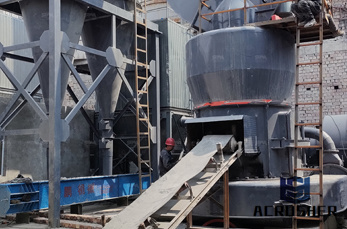

Coal Preparation Coal Processing Coal Handling. With coal preparation, raw coal is cleaned using different physical processes, with or without any chemical reagents, to get a product which can be sold in the market Coal preparation process starts with crushing and screening of freshly mined coal, which removes some of the noncoal material. Live ...

specialized heavy equipment and machinery, such as loaders, haulers, and dump trucks, which transport the ore to processing facilities using haul roads. This activity creates a unique set of environmental impacts, such as emissions of fugitive dust from haul roads, which an EIA for a proposed mining project should assess separately.

Coal can be extracted close to the upper portion of the earth''s crust, called surface mining, or from deep within the earth through underground mining. Recovering coal through surface mining is relatively easy; shovels and bulldozers are effective at extracting coal near the surface. Once depleted, workers replant a surface mine and move on.

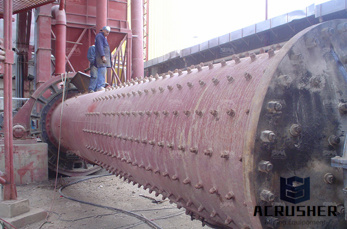

Crushers may be divided into three general classes, with respect to the manner in which they do their work: Pressure Crushers: This category embraces the several types of gyratory crushers and jaw crushers, as well as the double crushing rolls, with either smooth or corrugated shells. Impact Crushers: This division is represented chiefly by the various styles of hammermill; also by the cage ...

Introduction to Coal handling plant. In a coal based thermal power plant, the initial process in the power generation is "Coal Handling".So in this article i will discuss the overall processes carried out at a Coal Handling plant in a coal based thermal power generating station.

This process increases the heating value of the coal. Transporting coal. Coal can be transported from mines and processing plants to consumers in several different ways: Conveyors, trams, and trucks move coal around mines, short distances from mines to consumers close to the mines, or to other modes of longdistance transportation.

outside the mining area for placement and storage. In the Midwest, where the surface topography and coal seams are generally flat, it is common to employ area strip mining in which the fragmented overburden is placed directly by large draglines in the space created where coal has been mined ().In some situations in the eastern United States, a coal seam occurring near the top of mountains is ...

This page is devoted to the subject "From the Comminution Theory to Practice by selection of the correct Process Equipment" by taking you step by step through some of the variables encountered in the specific part of Comminution called grinding and how each of these affect your operations. Should it be possible to reduce all of these variables to a simple mathematical formula the selection ...

have led to different levels of preparation and the development of specific types of coal preparation plant design. Developments in processing techniques and processing equipment have also influenced the design and now give the preparation engineer numerous permutations in process and equipment .

The coal is then loaded on to large trucks or conveyors for transport to either the coal preparation plant or direct to where it will be used. Mine rehabilitation. Coal mining is only a temporary use of land, so it is vital that rehabilitation of land takes place once mining operations have stopped.

HMS and DMS are acronyms for Heavy (Dense) Medium Separation and is applied to the process of preconcentration of minerals – mainly the production of a high weight, low assay product, which may be rejected as waste. In principle it is the simplest of all gravity processes and is a standard laboratory method for separating minerals of different specific gravity.

Coal experience extends beyond the borders of Africa to China, USA, Australia, India, Russia, Trinidad and Indonesia. From feasibility studies and plant design, through to project implementation and process plant commissioning – DRA Global is able to provide the full spectrum of coal processing services.

Mining Operation: Types, Impacts and Remedial Measures! Mining is the process of taking mineral and other substances from the earth. These substances include metal compounds, nonminerals such as coal, sand, oil and natural gas and many other useful things.

broken coal into shuttle cars for delivery to a conveyor, and then bolting the mine roof in the excavated area. To provide a steady flow of coal in a roomandpillar mine, several stages of mining occur simultaneously in different rooms. A final phase of mining termed "retreat mining" may be performed to recover additional coal by

Chapter 19 Vocab STUDY equipment and approaches that seek to remove chemical contaminants such as sulfur during the process of generating electricity from coal fossil fuel produced by the conversion of organic pounds by heat and pressure crude oil is a mixture of hundreds of different types of hydrocarbon molecules . Live Chat

WhatsApp)

WhatsApp)