100ml Alumina Ceramic Grinding Jar with Lid

Compatible ball mill PQN04 Outer diameter (OD) 68 mm : Inner diameter (ID) 52 mm: Total height : 70 mm: Depth : 52 mm Al 2 O 3 content > 97% Density: g/cm 3: Hardness 9 .

WhatsApp)

WhatsApp)

Compatible ball mill PQN04 Outer diameter (OD) 68 mm : Inner diameter (ID) 52 mm: Total height : 70 mm: Depth : 52 mm Al 2 O 3 content > 97% Density: g/cm 3: Hardness 9 .

250 Ml Zirconia Milling Jar for Planetar, Yttrium Stabilized Zirconia Grinding Jar, Zro2 Zirconia Jar Mill manufacturer / supplier in China, offering Cylindrical Porcelain Ball Mill Pot, Plastic Combined Ceramic Pulley for Wire Guiding Wire Guide Pulley, Ceramic Idler Pulley for Cable Making Machine and so on.

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming ...

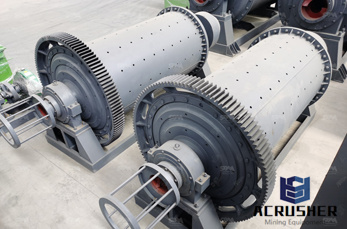

Ball Mill for Sale. APPROXIMATE CAPACITIES. All ball mills operate on the same principles. One of these principle is that the total weight of the charge in the millthe sum of the weight of the grinding media, the weight of the material to be ground, and any water in the mill—is a function of the percentage of the volume of the mill it occupies.

.GUI The PM 100 planetary ball mill is a benchtop unit designed to pulverize soft, fibrous and brittle materials. The mill develops extremely high centrifugal forces resulting in energy input that is up to 50% higher than in other planetary ball mills. It has a single grinding station for.

PM 100 and PM 200 planetary ball mill: Product Type: Grinding Jar: For Use With (Application) Ideal for extreme working conditions such as longterm trials, wet grinding, high mechanical loads and maximum speeds as well as mechanical alloying: Includes: Nonslip seating, builtin antirotation device, conical base centering, Oring, dustproof seal

Configure your Planetary Mill PULVERISETTE 5 premium line exactly to your specific application. The grinding bowls of the Planetary Mill PULVERISETTE 5 premium line are available in the sizes 125 ml, 150 ml, 250 ml, 420 ml and 500 ml. This gives you total .

Ball Mill 150 Ml. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment. And they are mainly used to crush coarse minerals like gold and copper ore, metals like steel and iron ...

The grinding bowls for the Planetary Mill Pulverisette 5 Premium are available in 150 ml, 250 ml and 500 ml sizes. This gives you flexibility for optimal adjustment to the specific sample volume. To achieve the best grinding results, and for direct prevention of contamination of the samples due to undesired abrasion, grinding bowls and balls ...

Stoneware''s unitized jar mills are engineered for economy, compactness and mobility. Assured reliability results from all welded steel frames, powerful roller chain drives, and pillow blocks with cartridgetype permanently sealed ball bearings for efficient operation.

Kit Includes 1 3 Lb. Rotary Ball Mill 100pc .455 Ball Mill Lead Media lbs. 1 Ball Milling Theory Practice for the Amateur Pyrotechnician by Lloyd Sponenburgh 3 Lb capacity media ball mill. This is a great compact mill for the hobbyist to mill black powder rocket propellant and other types of milling and grinding.

Polished 100mL stainless steel (grade 304 ) grinding jars for planetary ball mills. Each jar set includes grinding jar, lid, silicon sealing gasket and a mixed sizes of .

Shambhavi Impex Planetary Ball Mill, Ball Mill Machine, Planetary Ball Mill Manufacturer, Planetary Ball Mill Exporter from india. An ISO 9001:2015 Certified Company. Send Email. ... 500 ml, 250 ml, 150 ml and 100 ml. Salient Features. Advantages: Micron sub micron generation. Four samples can be made at .

MSKPCV310A is a compact single container centrifugal mixer designed for mixing and ball milling various kinds of liquid, slurry, paste, and powder materials, especially some highviscosity materials. The mixing and ball milling capability is integrated into the best performance results. The standard package includes one 300L of container and counterweights with optional jar and adaptors.

Disc Mill: 150 kg/h: User selectable: Fritch P13 Premium: 12 mm: 1020 m: Ring Disc Mill: 250 mL: User selectable: Fritsch P9: 15 mm <40 m: Rotor Mill: 15 kg/h: SS or Titanium: Fritsch P14 Premium: ... Mini Ball Mill: 5 mL: User selectable: Fritsch P23: Cutting Mills, Cross Beater Mill: 120 x 85 mm: 1 mm: Cutting Mill: 85 L/h: User selectable ...

Depending upon the model, sample quantities can be as low as 20 ml or up to 20,000 ml. Horizontal Bead Mills: Our Dispermat SL model line is the current horizontal bead mill system. Milling chamber sizes can start at 50 ml to save on raw material costs. The beads are separated from the mill base by a dynamic gap system.

MK 300 150–3000 37 830 600 1220 650 MK 320 200–5000 37 830 600 1220 650 Perforated disc mill (ML) Corundum stone mill (MK) Toothed colloid mill (MZ) For over 65 years, FrymaKoruma has been a leading international supplier of processing machinery and equipment for the pharmaceutical, cosmetics, food and chemical industries.

Make sure this fits by entering your model number.; Product Description: Polytetrafluoroethylene (PTFE) has the reputation of "king of plastics". The ball mill tank made of PTFE has excellent chemical stability, wear resistance, corrosion resistance, sealing, high lubrication and nonviscosity, electrical insulation and antiaging ability, and can work stably for a long time from 180 to 250 ℃.

Buy Agate jar f/ball mill, 250 mL in Auxilab, the online shop of laboratory equipment at the best price X We use cookies to ensure that we give you the best experience on our website.

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary ...

ball mill 150 ml Laboratory Crushers, Pulverizers, Grinders | Laval Lab The High Energy Planetary Ball Mill Pulverisette 5 PREMIUM with 2 working stations is the ideal mill for fast, wet or dry, grinding of larger sample quantities down to .

Working Principle Operation. The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball mills designated as 5′ x 5′ where the ...

Planetary ball mill jar includes cup/bowl, lid and gasket. Polyurethane/PU Milling Jars for Planetary Mill Price Product # Volume (ml) Price (USD) JA0609 50 139 JA0602 100 169 JA0600 250 199 JA0610 500 249 JA0604 1,000 369 JA0601 1,500 469 JA0606 2,000 559 JA0605 2,500 599 JA0608 3,000 839 JA0607 4,000 939 JA0611 5,000

The extremely high centrifugal forces of planetary ball mills result in very high pulverization energy and therefore short grinding times. The PM 400 is a robust floor model with 4 grinding stations. You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy input. The unique combination of high ...

WhatsApp)

WhatsApp)