Ball millPrinciple, Advantage, Disadvantage YouTube

Aug 05, 2020· Hello Guys Welcome to my YouTube channel "Pharma Learning with Deepika". In this video lecture I have covered the Ball mill: Principle, working, .

WhatsApp)

WhatsApp)

Aug 05, 2020· Hello Guys Welcome to my YouTube channel "Pharma Learning with Deepika". In this video lecture I have covered the Ball mill: Principle, working, .

Size Reduction. Tumbling Steel Ball Mills and Ceramic Lined Mills are one of the most precise, reliable and cost effective methods of fine grinding solids in either a wet or dry Mills are referred to by many names including Pebble Mills, Tube Mills and Attrition Mills, but no matter what the nomenclature they all operate on the same efficient principle.

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case". Well, this safety factor can cost you much in recovery and/or mill liner wear and ...

The big end was 2 feet in diameter and the small end 1 foot. The ability of the mill to segregate the balls was demonstrated by tests. Grinding tests with several types of mills and ball loads led to the conclusion that advantages that had been gained were due more to the appropriate average size of balls than to the new design of mill.

Shape – balls, beads and satellites satisfy the bulk of our customers'' requirements, but we also source highly specialized shapes like ballcones and diagonals Diameter – depending on the material, ranging from mm to 2 mm for small media mills, up to 1/8" to 1" for traditional Attritors and up to ½" to 2" for ball mills

This is an old word with many uses and distinguishing grinding mills from the rest is very useful. The assertion above that Mill (grinding) is the primary topic for mill is untrue. I have no opinion on the proposed change to the Mill page itself. Gravuritas 18:10, 20 December 2017 (UTC) Here''s an example of non grinding mills.

Jul 31, 2020· We see no difference with Ball Mill #3. We did all the tieins earlier in the year. A lot of the construction activities take place in what is an existing empty bay right now.

For overflow ball mills, the charge should not exceed 45% of the mill volume . For grate discharge mills, the charge should occupy about 50% of the mill volume . Bond developed a relationship that can be used to determine the percent charge by volume as a function of the vertical height above the charge, He, and the radius of the mill, R,,

Jun 20, 2019· For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 3045%). Pulp (crushed ore and water) fills another 15% of the drum''s volume so that the total ...

This article on choosing milling media for a ball mill by Ned Gorski is a side article that goes with the "Ball Milling 101" Media Cautions. In his book Ball Milling Theory and Practice for the Amateur Pyrotechnician, Lloyd includes a section on casting your own lead media.

Carbide ball end mills provide excellent wear resistance and heat resistance, and they are harder than highspeed steel, powdered metal, or cobalt steel ball end mills. Also known as ballnose end mills, ball end mills have a rounded nose and create a roundbottomed groove in milling tasks.

Durability: 100,000 to 1,000,000 Cycles Current Rating: continuous, 5A peak Contact Resistance: 20 mΩ Max Operating Temperature Range:55/+125° C (discontinuous) Vibration: No Elect. Discontinuity > 1μs 0200 Hz, 10g Shock: No Elect. Discontinuity > 1μs 50g

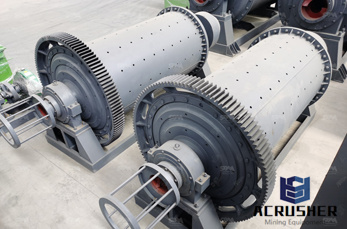

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

The maximum power draw in ball mill is when ball bed is 3540 % by volume in whole empty mill volume. Considering that ball bed has a porosity of 40 %, the actual ball volume is considered to be ...

Hammer mill is the most widely used grinding mill and among the oldest. Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case. It produces size reduction by impact.

Molinos De Bolas Cod No 10 518 0000, Ball mill adityapur ball mills cod no 10 518 0000 assetcare companys name service is the commitment of enterprise soul of brand so skd integrates service into each segment of the life cycle from presale insale until Ball Mills Cod No 10 518 0000

Date HS Code Description Origin Country Port of Discharge Unit Quantity Value (INR) Per Unit (INR) Nov 02 2016: : PLANETARY BALL MILL PM 100 () Germany

This extreme flexibility enables a MUNSON ® Pin Mill, with no modifications, to grind friable materials into tight size ranges from coarse particles down to powders of 400 mesh, and to delump agglomerated material. Materials remain cooler than in other types of mills since retention is minimal and air is constantly drawn through the mill chamber.

The vertical ball mill is used for the processing of highviscous premixed pastes, like chocolate, compound, crèmes, nut and seedpaste. The continuous design vertical ball mill can be used in a 1 – 3 stage refining system, with 1 – 3 ball mills in a sequential row after the premixer.

50Pack Brag Dog Tag Ball Chain Necklace Bulk Nickel Plated Adjustable 24 inches Long Bead with Matching Connector Clasp for Kids Boys Students Men Women Jewelry Making. out of 5 stars 574. 8. 99. Get it as soon as Wed, Aug 12. FREE Shipping on .

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming ...

Each ball mill is turned by a single 3,000 horsepower electric motor. These mills contain literally hundreds of thousands of threeinch diameter steel balls that pulverize the ore until it is like fine sand or face powder. Only then are the copper minerals broken .

Find here Used Ball Mills, Second Hand Ball Mills manufacturers, suppliers exporters in India. Get contact details address of companies manufacturing and supplying Used Ball Mills, Second Hand Ball Mills across India. ... Call +. Contact Supplier Request a quote. Old Used Second Hand Ball Mill Ask Price.

Ball mills are a fundamental part of the manufacturing industry in the USA as well as around the world. Ball mills crush material into various sizes and extract resources from mined materials. Pebble mills are a type of ball mill and are also used to reduce the size of hard materials, down to 1 micron or less.

WhatsApp)

WhatsApp)