Iron Ore: Key Themes To Consider | Seeking Alpha

Jun 11, 2020· Iron ore has been one of the betterperforming commodities in 2020, supported by demand from Chinese steel mills and supplyside disruptions in Brazil. Australi

WhatsApp)

WhatsApp)

Jun 11, 2020· Iron ore has been one of the betterperforming commodities in 2020, supported by demand from Chinese steel mills and supplyside disruptions in Brazil. Australi

major equipment for iron ore mills. Iron and steel industry in the United States Wikipedia:The traditional large integrated steel mill which reduces metallic iron from ore iron oxide and makes it into pig iron and steel has been steadily declining in importance for decades in the US The second type the minimill or specialty steel mill which produces new steel products by melting steel scrap ...

Aug 12, 2008· Woodward Iron Company Four ironmaking enterprises, each controlling substantial deposits of iron ore, coal, limestone and dolomite, came to dominate the industry. These companies were unique in their use of advanced blastfurnace plants that smelted iron ore into pig iron. Woodward Iron, Sloss Sheffield Steel and Iron Company, and Thomas Works operated blastfurnace plants that .

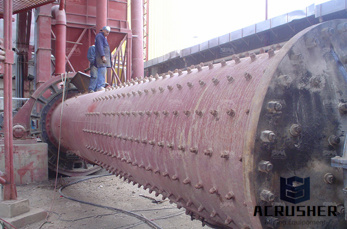

sudan iron ore dry ball mill equipment. The Major Equipment of Iron Ore Processing Plants Iron Ore Processing Plant isposed of jaw crusher, ball mill, spiral classifier, mixer,ic separator, ore concentrator and dryer machine,bined with ore feeder, bucket elevator and belt ore beneficiation production line can be formed.

Iron Ore Formation. Iron formation consists of iron ore such as siderite, magnetite, and hematite, with silica in the form of chert, jasper, etc., generally in bands, but sometimes not distinctly so. The bands of iron ore are at times highgrade, but are often mixed with a good deal of silica, the whole making an ore too lean for use without ...

Metallurgical Testing for Iron Ore SGS equipment to use for gravity separation of iron ores because of the high throughputs needed. SGS has a variety of spiral test rigs, including the spiral designs typically used in iron ore plants. Our accessory equipment allows sizing of feeds, multiple spiral iron ore rod mill processing for copper ore india iron ore rod mill processing for copper ore ...

SAFETY GUIDELINES FOR IRON STEEL SECTOR MINISTRY OF STEEL, Doc. No: DG/40 GOVT. OF INDIA PELLET PLANT . The location of a pelletizing plant affects the method of receiving raw materials such as iron ore, additives and binders. Pretreatment process of Iron Ore Fines In the pretreatment process, iron ore fines are ground into finer size, suitable for green ball

Iron Ore Grinding Mill Data. As a global leading manufacturer of products and services for the mining industry, our company can provide you with advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete plant plan.

Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring grinding as fine as minus 500 ...

Mar 14, 2019· As a necessary input for the production of primary steel, iron ore feeds the world''s largest metal market and the backbone of global trilliondollarayear steel market accounts for 95 percent of all metal sold every year. And, in order to satisfy our demand for steel products, billion tonnes of iron ore were mined in 2014.

Iron Mining Equipment for Sale. Construction Waste Crusher. ... It is the major production and export base of roller mills and crushing equipment in China. It always pays moattention to keep pace with the times. SBM pursues the excellence. It constantly absorbs the highquality management personnel and scientific elite, introducing advanced ...

200 Public Square, Suite 3300 Cleveland Ohio, United States ...

Each primary mill contains several 4" steel balls that grind the ore as the mills turn. When the ore is reduced to 3/4" or less, it moves out of the mill in a slurry solution. The mill discharge is screened at 1/4" on trommel screens attached to the mill. Ore smaller than

equipment to use for gravity separation of iron ores because of the high throughputs needed. SGS has a variety of spiral test rigs, including the spiral designs typically used in iron ore plants. Our accessory equipment allows sizing of feeds, multiple spiral stages, and recycling of products. Other gravity separation equipment,

major equipment for iron ore mills. HGT Gyratory Crusher. Steel Manufacturing Industry: Career Outlook and . The steel industry consists of EAFs and integrated mills that produce iron and steel from scrap or iron ore Most of these mills also have finishing mills on site that convert iron and steel into both finished and unfinished products Some ...

major equipment for iron ore mill. Get Price And Support. Iron and Types of Iron Iron is a chemical element with symbol Fe (from Latin word Ferrum). Its atomic number is 26 and atomic mass is . ... All of the iron ore that is mined in the UP of Michigan and in northern Minnesota is moved out of .

A major environmental hazard associated with integrated steel mills is the pollution produced in the manufacture of coke, which is an essential intermediate product in the reduction of iron ore in a blast furnace. Integrated mills may also adopt some of the processes used in minimills, such as arc furnaces and direct casting, to reduce ...

Iron Ore Machine Iron Ore Plant Machinery And Equipment. The Major Equipment of Iron Ore Processing Plants Iron Ore Processing Plant is mainly composed of jaw crusher ball mill spiral classifier mixer magnetic separator ore concentrator and dryer machine and combined with ore feeder bucket elevator and belt. Get Price

Types Iron Ore Mining Equipment Iron Ore Grinding Mill Sale. Milling Equipment: types iron ore mining equipment iron ore grinding mill sale A class of machinery and equipment that can be used to meet the production requirements of coarse grinding, fine grinding and super fine grinding in the field of industrial finished product can be controlled freely from 0 to 3000 mesh.

Exercise Equipment Tread Mills Iron Ore Mining Machinery. Pier or occupant and upon the mining plant, machinery, equipment. and buildings used for or 1il connection with the actual mining operations, or for storing the ore or mineral 11 an allowance of a sum for annual depreciation, by ordinary wear and tear, of the said plant. machinery, equipment, and buildings, such sum to be based. get price

The mill is driven by a girth gear bolted to the shell of the. vessel and a pinion shaft moved by a prime mover. is charged with the starting material ore, rock, etc. equipment used to load the starting material feeders, and the system PELLET FEED GRINDING PROCESS MetalMat UFRJ PBM Approach to Ball Mill Optimization in Iron Ore Grinding ...

Most iron and steel in the United States is now made from iron and steel scrap, rather than iron ore. The United States is also a major importer of iron and steel, as well as iron and steel products. Employment as of 2014 was 149,000 people employed in iron and steel mills, and 69,000 in foundries.

Ball Mill Iron Ore Processing Equipment. Operation Principle of Iron Ore Ball Mill Xinhai Iron ore ball mill is the major mining processing equipment today, after a number of improvements, on its basis depending on the grinding required to produce a number of different models. The grinding operation of Iron ore ball mill . Click Here

Major Equipment For Iron Ore Mills. This series of equipment is the necessary process of ore processed into many industries required materials products required mining equipment. So the iron ore market development, not only lead to the development of machinery industry, also leading the development of the crusher and other crushing equipment. ...

WhatsApp)

WhatsApp)