OK™ Mill working principle by FL YouTube

Feb 10, 2017· 50+ videos Play all Mix OK™ Mill working principle by FL YouTube KMC CMP AVI 05 Vertical Roller Mill Duration: 12:46. Versatylo Interactive 9,851 views

WhatsApp)

WhatsApp)

Feb 10, 2017· 50+ videos Play all Mix OK™ Mill working principle by FL YouTube KMC CMP AVI 05 Vertical Roller Mill Duration: 12:46. Versatylo Interactive 9,851 views

Denmark: FL says it sold 31 new vertical roller mills (VRM) in 2018 for all grinding applications. The combined cement grinding capacity of its OK Mills VRM product line grew by over 38% yearonyear to 3145t/hr in 2018 from 2270t/hr in 2017. The average grinding capacity per sale of OK Mills for the cement industry grew by almost 10% to ...

FL will deliver stateoftheart energyefficient technology including vertical roller mills for raw, coal and cement grinding, FL CrossBar® cooler, and a LowNox InLineCalciner kiln system. The client, Cielo Azul, is an established player in the Ready Mix Concrete (RMC) business in which concrete is delivered directly to the ...

A fullscale threecompartment FL® cement grinding ball mill with dimensions of Ø × L10 operating in open circuit was sampled to analyse the grinding media effect on specific breakage rate function of reduction performance of the ball mill was evaluated with respect to the applied grinding media size.

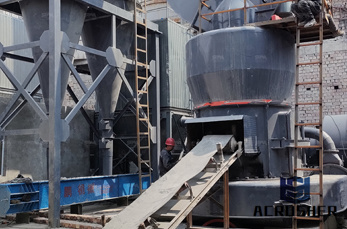

Vertical Roller Mills (VRMs) have been the standard option for raw materials grinding in the cement industry for several decades. FL has supplied the global cement industry with leading VRM designs for all applications since they were first brought to market. The OK™ mill has been FL''s standard cement VRM since 1993.

Improving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical roller mill grinding installations. Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and pet coke, and finish cement grinding.

Summary: The main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system simplicity. In the case of new orders, vertical mills have increased their share to over 60 % and ball mills have fallen to less than 30 %. It is somewhat surprising that the number of different grinding processes and mill types used by the ...

FL delivers sustainable productivity to the global mining and cement industries. As the marketleading supplier of engineering, equipment and service solutions, FL improves performance, drives down costs, and reduces the environmental impact of operations. Present in more than 50 countries and headquartered in Copenhagen, Denmark ...

The order will include an ATOX vertical mill for raw grinding, an ATOX vertical mill for coal grinding, an EV 200x300 Hammer Impact Crusher, stacker and reclaimer systems for storage, a ROTAX2 rotary kiln with low NOx ILC calciner, a FL CrossBar cooler, a JETFLEX burner and two OK 394 vertical mills for cement grinding.

The OK mill has been FL''s standard cement vertical roller mill (VRM) since 1993. In 2017, FL also introduced the OK raw mill for raw material grinding, designed with the same proven design as the OK cement mill. The common mill platform implies parts commonality that allows owners to benefit from reduced spare parts inventory as ...

The Mojave plant already operates a 2004 FL OK cement mill, which means the plant can streamline maintenance and better manage inventory costs, as both mills share the same gearbox design an FL MAAG WPU200 assembly. "CalPortland''s continued confidence in our OK Mill platform demonstrates the strength of one of our flagship ...

A Ball mill is a horizontal cylinder partly filled with steel balls (or occasionally other shapes) that rotates on its axis, imparting a tumbling and cascading action to the balls. Material fed through the mill is crushed by impact and ground by attrition between the balls. The grinding media are usually made of highchromium smaller grades are occasionally cylindrical ("pebs ...

Dec 19, 2018· The FL OK 816 Mill has an grinding table and six grinding rollers powered by two FL MAAG Max Drive gear systems. FL says that the mill is the largest VRM ever to be installed in a cement plant in terms of dimension, operating capacity and installed power. It was put in operation in September 2018

Jun 23, 2016· Media Relations: Sofie Karen Lindberg on +, or skl FL is the marketleading supplier of productivity to the global minerals and cement industries.

June 23, 2015 Ball Mill, Cement, Cement Mill, Engineering, FL Co. A/S (Business Operation), Grinding, Training FL has designed a series of online training for the cement industry, providing you with easy and instant access to our specialised technical training.

Feb 05, 2020· FL delivers sustainable productivity to the global mining and cement industries. As the marketleading supplier of engineering, equipment and service solutions, FL improves performance, drives down costs, and reduces the environmental impact of operations. Present in more than 50 countries and headquartered in Copenhagen, Denmark ...

Cement grinding with our highly efficient ball mill An inefficient ball mill is a major expense and could even cost you product quality. The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance.

Jun 24, 2015· A ball mill''s components and the components'' functions, and on 4. Cement grinding systems with primary focus on closed circuit operation. This clip shows an example of an exercise in the course.

Bangladesh: FL has confirmed that is to supply a cement grinding production line for Meghna Cement Mills. The Danish equipment manufacturer has signed a contract with Meghna Cement Mills for engineering, procurement and supply of equipment for a 415t/hr Portland composite cement at 3800 Blaine grinding unit at it plant in Mongla in the Bagerhat District.

Jun 24, 2015· 1. Safety around a ball mill 2. An overview of a ball mill 3. A ball mill''s components and the components'' functions, and on 4. Cement grinding systems with primary focus on closed circuit ...

mill operations, the energy requirements for the OK cement mill is 3045 percent lower for cement grinding and 4050 percent lower for slag. The OK mill can contribute significantly to profitability and competitiveness. The design combines the drying, grinding, material conveying and separation processes into just one unit, thus simplifying the ...

All cement grinding ball mill systems Fully or semi airswept raw grinding ball mills ... system for removal of worn grinding media from the mill discharge material means less clogging of diaphragms. ... FL A/S Vigerslev Allé 77 DK2500 Valby Copenhagen Tel: +45 3618 1000

In the period 2009 to 2015, of the 1209 new mills that were ordered by the cement industry outside China, 661 units or 55 % were VRM, the remaining 45 % were other types such as ball mills, highpressure grinding rollers (HPGR) and horizontal mills. Figure 1 shows how the mill market potential developed and how the market share of VRM changed.

FL has been chosen by San Miguel Northern Cement Inc., Ionic Cementworks Industries Inc. and Oro Cemento Industries Corporation for engineering and procurement to supply four OK 564 vertical roller mills for cement grinding. The OK mills will be located at different locations in the Philippines. Since 1980, FL has been present in ...

WhatsApp)

WhatsApp)