magnetite iron ore price per ton Simurgh iron and steel ...

Jul 23, 2019· The magnetite iron ore price per ton, iron pellets and concentrates is at the peak of several years. Iron and steel prices have made unprecedented leaps in the first half of .

WhatsApp)

WhatsApp)

Jul 23, 2019· The magnetite iron ore price per ton, iron pellets and concentrates is at the peak of several years. Iron and steel prices have made unprecedented leaps in the first half of .

28 Jan 2010. tonne per annum mine plan (CAD per tonne of mill feed) over the . of the delivered price of DMSgrade magnetite, alternative sources of. » More detailed Iron Ore – Monthly Price – Commodity Prices – Price Charts, Data .

ZINC MINING RAMBLINGS MODULE 1 HOW MUCH IS THE ORE WORTH? Rev 0 JULY 2016 1 Doug Beattie, Mining Engineer (Retired) ... Revenue must be related back to the cost of mining, milling and all other site and corporate charges on a ... per tonne of ore?

Generate Total Services Cost per Blast ton. Operating Cost Basis ITH Supply Drill Costs ... Processing Cost Ore and Waste Handling Underground Services UG Utilities In Stope Mining Cost 207 147 210 130 106 ... cost Milling Mining Drill Blast Backfill Development Ore Waste Movement Mine General Cost Profile METAL PRICE

From the data in Table 1 and Fig. 3 it is apparent that the production of hot metal or pig iron is the most energy intensive process for steel production at roughly × 10 9 joules per ton (1000 Kg) of pig iron produced. The basic oxygen furnace is the second most energy intensive process at 11 × 10 9 joules per ton or steel produced. The Electric arc furnace has significantly less energy ...

Derived Energy Consumption and Costs: • Per Tonne Ore Hoisted • Per Tonne Ore Milled/Concentrate • Per Unit: Metal(s) Production Sample of Underground Mines 1 AME MINERAL ECONOMICS, LEAD AND ZINC 2000, GOLD 2000, AND COPPER 2000 – MINE COSTS 1994–2005, 1999.

Copper has recovered from sixyear lows struck late August on the back of supply cuts by major producers but at around a pound or 5,000 per tonne on Tuesday there isn''t much breathing ...

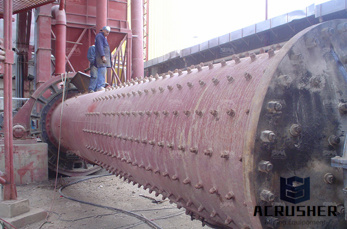

Iron Ore Processing for the Blast Furnace (Courtesy of the National Steel Pellet Company) The following describes operations at the National Steel Pellet Company, an iron ore mining and processing facility located on the Mesabi Iron Range of Minnesota. Creating steel from lowgrade iron ore requires a long process of mining, crushing,

Recent iron ore and coal prices can be found on our steelmaking costs page. Analysis above was prepared in July 2019. The Steel Product The steel product for which the cost is shown above is a metric tonne of BOF liquid steel. The cost is for a notional producer .

decreased first cost of concentrating plants per ton of daily capacity and decreased operating and repair costs per ton of ore treated; decreased costs of milling and mining operations and improved metallurgical results, permitting lowergrade copper ores to be mined and treated and thereby increasing the available ore reserves of many ...

The miner''s overall cost of production has dropped since 2015 to 48 per wet metric tonne for its iron ore. Mount Gibson''s major shareholders are Hong Kong commodities investor APAC Resources and ...

Aug 03, 2016· According to its halfyear financial report the company''s Pilbara unit cash costs fell to per tonne in 2016 first ... So far this year iron ore is averaging around 52 a tonne, flat ...

Get Latest Manganese Ore Price Chart Of Barbil, China, Balaghat. Also Find MOIL And UCIL Manganese Ore Price Trend And Imported Manganese Ore Price. Get Global Price Of Manganese Ore Per Metric Ton | SteelMint

The cost data above referred to has been compiled from actual operating results and shows the cost of milling both for the old 50ton plant and the new 100 ton concentrator, as is now in use. Note the reduction in milling costs through the use of the new flowsheet which includes an 8cell "SubA" Flotation Machine.

The operating staff is thus reminded that maximum efficiency results from minimum cost per ounce of metal rather than minimum cost per ton of ore, which should have a salutary effect when such questions as control of dilution and grade of ore in mining and loss of metal in milling are considered. Cost per ounce of gold is given for a few gold ...

Note that capital costs are expressed in dollars and operating costs in dollars per short ton of material (ore and waste) mined. All costs are based on daily capacity of the mine (X) in short tons per day of material (ore and waste) moved. Figure 2 summarizes the cost curves for the base case total cost .

kilowatthour (kWh) per unit basis, primarily the metric ton (ton) or troy ounce. Data contained in tables pertaining to specific currently operating facilities are static, as the amount of electricity consumed to process or produce a unit of material changes over time for a great number of reasons.

1,818 lead ore price products are offered for sale by suppliers on, of which mine mill accounts for 25%, other mining machines accounts for 1%, and lead accounts for 1%. A wide variety of lead ore price options are available to you, There are 1,813 suppliers who sells lead ore price on, mainly located in Asia.

This mine is an open pit mine producing 5,000 tonnes ore and 5,000 tonnes waste per day. Rock characteristics for both ore and waste are typical of those of granite or porphyritic material. Operating conditions, wage scales, and unit prices are typical for western mining operations. All costs listed are in 2012 US.

Power and fuel expenditure, largely due to diesel consumption for onsite power generation, together comprise almost 15% of costs. Annual unit operating costs per tonne ore milled and total operating costs for the Financial Base Case are shown in Figures 6 and 7. Figure 6 – Updated FS – Annual unit operating costs per tonne milled

Apr 08, 2015· Here are the breakeven costs for Australia''s iron ore miners ... iron ore was per tonne – a far cry from the more than 100 it was fetching early last year. ... only BHP, Rio Tinto ...

After the Chinese government announcement, the price of ore with 62 percent content jumped to a dry metric ton. These are mostly in futures prices, because there has not yet been any increase in physical orders for iron ores. The stocks of producer companies also increased in price.

The COG calculation integrates multistaged costs and efficiencies from extraction through to refining, all of which are required to realise quoted market prices. Ore operating cost reflects multiple concentrating stages whose unit costs are measured in different denominations, such as: process costs per tonne of mill feed, mining costs per ...

Chrome ore firms up in auction, rises over 50% | Business Standard. 27 Feb 2013 . The price of the 54 grade chrome ore went up to Rs 17,073 a tonne, against Rs 11,087 a tonne in December. This is a jump of 54 per cent. »More detailed

WhatsApp)

WhatsApp)